AWD-H Haldex Fluid

Oil test analyse AWD-H Fluid

▶ HALDEX SYSTEM

The Haldex system is a type of AWD system that is normally used in Volkswagen Group vehicles. It is often found in Volkswagen and Audi vehicles. The main function of the Haldex System is to transmit torque from the engine to both axes.

Example using a front-wheel drive car:

Under normal conditions, approx. 95% of the power is diverted to the front wheels. When the electronically activated clutch is engaged, the power is diverted 50/50 to the rear wheels due to the spinning of the front wheels. The Haldex sensor allows very little rotation before engaging.

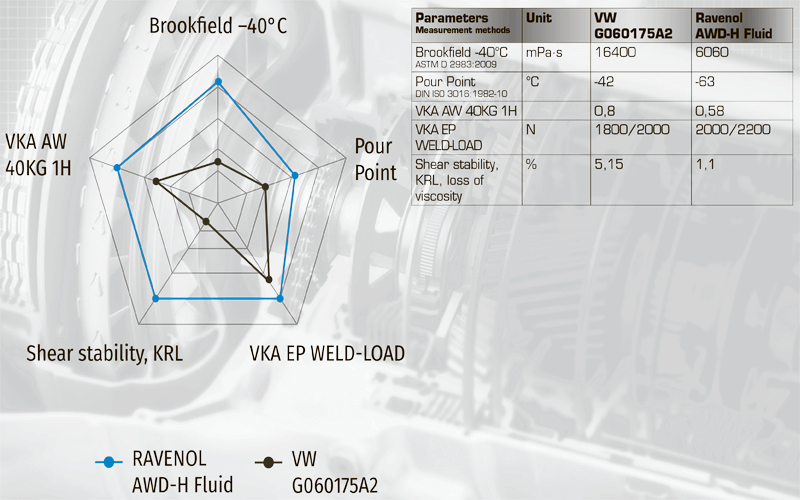

▶ RESULTS OF THE OIL ANALYSIS

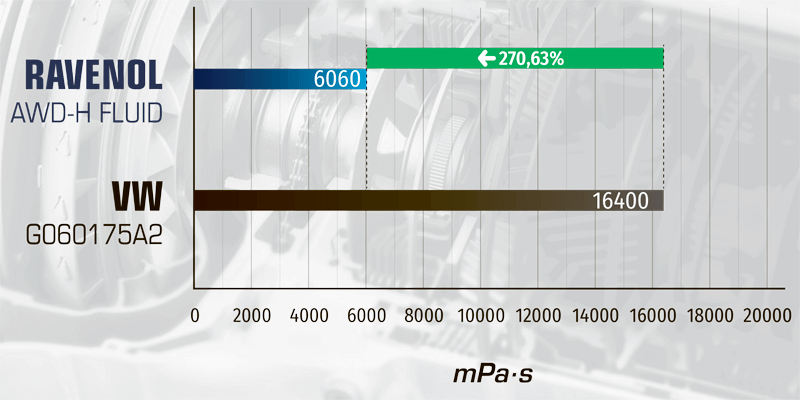

▶ BROOKFIELD -40°C

▶ ASTM D 2983

The Haldex clutch will begin to work faster, the oil will circulate more quickly and there is no wear caused by a low temperature start. With regard to the parameters for dynamic viscosity at minus 40 °C,

The lower the dynamic viscosity, the better. RAVENOL AWD-H Fluid delivers 270.63% higher performance than the original oil VW G060175A2.

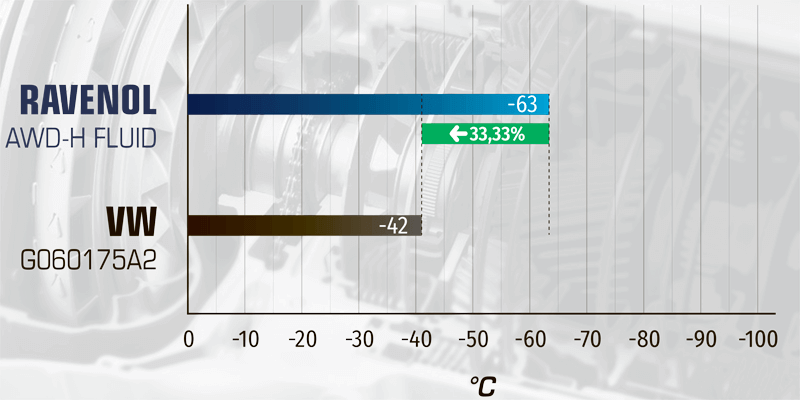

▶ POUR POINT

DIN ISO 3016

Describes the lowest temperature at which the oil remains fluid and can be used as intended.

At its pour point, RAVENOL AWD-H Fluid delivers 33.33% higher performance than the original oil VW G060175A2.

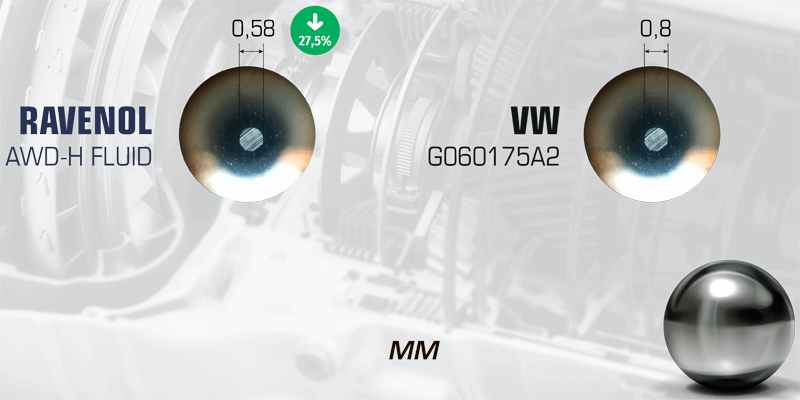

▶ MEASUREMENT OF WEAR PROTECTION AND PRESSURE LOAD PROPERTIES

FBT = FOUR BALL TESTER

WEIGHT 40 KG CYCLE TIME 1 HOUR

The RAVENOL four-ball tester according to DIN 51350 is used to determine the values for lubricants which are exposed to surface pressure in a system with parts in relative motion to one another. In addition to the shear stability at high pressures, the wear protection behaviour when the pressure build-up is low can also be determined.

The four-ball tester is a common test procedure in the lubricant industry and it is used for product development and quality control.

The four-ball system consists of three fixed balls of the same size (stationary balls) and one rotating ball (load ball). The lubricant being tested is then poured over the stationary balls until they are completely covered. Using a lever device and a staged regulation of the test weights, different loads are generated and the corresponding characteristic values for abrasion, friction and welding are determined.

The higher the welding force or the lower the wear values of an oil or grease, the better its wear protection when subjected to pressure load.

RAVENOL AWD-H Fluid delivers 27.5 % higher performance than the original oil VW G060175A2.

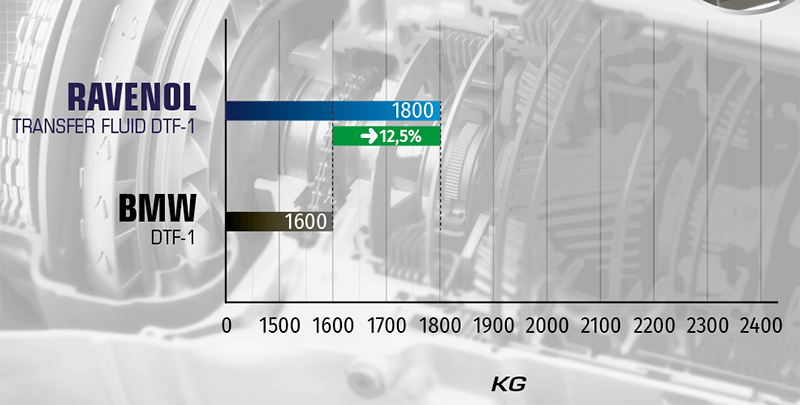

▶ VKA EP WELD-LOAD

Four ball test – Extreme pressure

DIN EN ISO 20623:2018-04

This process is particularly used for lubricants that have to withstand high loads and pressures. Contained EP additives enable high pressures in the mixed friction area. The four-ball value is given in N (Newtons).

The higher the strain it withstands, the better.

RAVENOL AWD-H fluid withstands 10% more strain than the original oil VW G060175A2.

▶ SHEAR STABILITY, KRL, LOSS OF VISCOSITY

DIN 51350-6

TAPERED ROLLER BEARING TEST 20-HOUR

KRL test to determine viscosity changes in multigrade oils, usually gear or axle. The viscosity improver in these oils can be severely sheared during operation. As a result, the oil becomes thinner over time. The KRL test uses the four-ball device to measure the change in viscosity associated with the decrease in viscosity index (VI) improver. Instead of the four balls, this test is carried out with a tapered roller bearing with about 40 ml of oil. With the splash lubrication method, the oil is sheared with the rotating tapered roller bearing at a temperature of 60 ° C, a constant load of 5,000 N and usually over a period of 20 hours. The resulting relative viscosity drop at 100 ° C is given as a percentage.

RAVENOL AWD-H Fluid is 4.7 times better than the original oil.

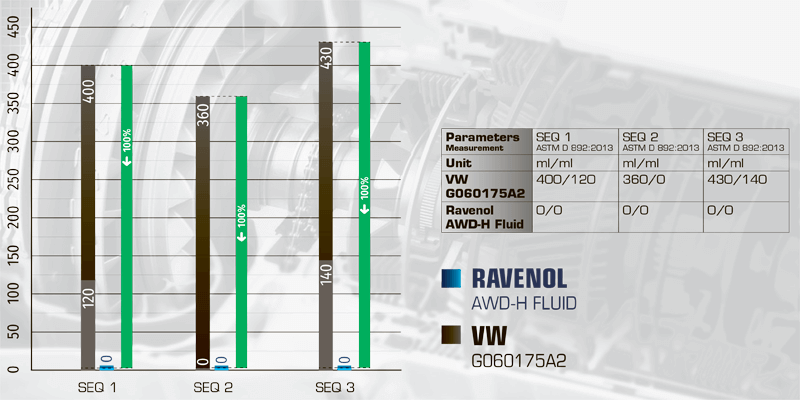

▶ FOAM TEST

The foaming tendency of lubricants can deteriorate as a result of impurities and oxidation. Excess foam can reach areas under high strain and impede the development of a hydrodynamic lubricating film. Surface foam can cause leaking, if foam swells through seals and ventilation spouts. Foam occurs when gas bubbles from the oil rise to the surface and do not burst. This can be due to the high surface tension

▶ COPPER STRIP TEST: EFFECT OF CORROSION ON COPPER

▶ ASTM D130: 2012

Test duration 3 hr

Temperature: 150 °C

The procedure determines the corrosive effects of lubricating oils and greases on copper. Corrosion to metal is based on factors including but not limited to active sulphur compounds in the oil. The level of corrosion at the end of the experiment is ascertained by comparing the copper strip with a colour scale. The result is placed in one of four main categories (1-4) and, within these, two to five sub-categories (a-e).

Lighter better

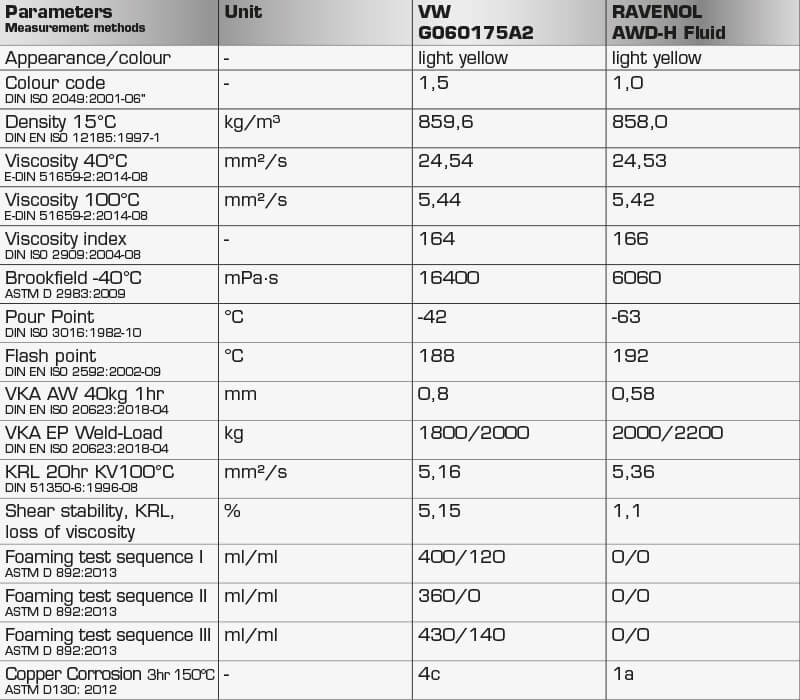

▶ TEST RESULTS